British Stirling Engine helps electricity production…. (and it’s solar)0

The Stirling engine (or Stirling’s air engine as it was known at the time) was invented and patented by Robert Stirling in 1816. The Stirling engine was developed by Reverend Robert Stirling in Edinburgh in 1816 as an alternative to the steam engine. It uses alternate heating and cooling of an enclosed gas to drive pistons, which turn a flywheel. Originally conceived in 1816 as an industrial prime mover to rival the steam engine, its practical use was largely confined to low-power domestic applications for over a century.

Now a Swedish company is using the old technology in it’s record breaking solar panels.

Ripasso has claimed it has produced a new solar electricity generation system that is the most efficient in

the world. It is currently being tested in South Africa’s Kalahari desert and recent test have shown that it is converting 32% of the suns energy to grid available electric power as opposed to the 15% we currently get out of standard photovoltaic panels.

The panels themselves look like massive satellite dishes. These 100 metre square dishes slowly follow the sun, constantly capturing the maximum solar energy. UK company IT Power, a World leading renewable energy consultancy firm, were commissioned in 2014 to test the technology. The results showed a single dish can generate up to 85 megawatt hours of electricity a year which is enough to power 24 UK homes.

The technology works by using the mirrors as giant lenses that focus the sun’s energy to a tiny hot point, which in turn drives a zero-emission Stirling engine. Unfortunately Ripasso’s new solar panels are not destined for our shores however as the system is only useful in areas with constant bright sunshine.

The technology works by using the mirrors as giant lenses that focus the sun’s energy to a tiny hot point, which in turn drives a zero-emission Stirling engine. Unfortunately Ripasso’s new solar panels are not destined for our shores however as the system is only useful in areas with constant bright sunshine.

Due to material limitations at the time, the advanced Stirling engine that Ripasso uses was not commercially developed until 1988, when Swedish defence contractor Kokums started making them for submarines. Because the Stirling engine is compatible with alternative and renewable energy sources it could become increasingly significant as the price of conventional fuels rises, and also in light of concerns such as peak oil and climate change. This engine is currently exciting interest as the core component of micro combined heat and power (CHP) units, in which it is more efficient and safer than a comparable steam engine. Brings meaning to the saying “there’s life in the old dog yet!”

Dyson to see it’s name in Lights0

No, I am not announcing a film about vacuum cleaners or the British inventor Sir James Dyson but rather to the news that his son Jake Dyson has launched a range of LED lights that are said to have an expected life of more than 35 years.

We are seeing more and more homes, commercial and industrial buildings switch to LED lighting, even american airline Delta have announced that they are to spend 3 years refitting all of their planes with LED lighting. This could apparently save the airline $50,000.00 a year per plane which makes me think they would be stupid to not do it and why is every airline not doing it?

We are seeing more and more homes, commercial and industrial buildings switch to LED lighting, even american airline Delta have announced that they are to spend 3 years refitting all of their planes with LED lighting. This could apparently save the airline $50,000.00 a year per plane which makes me think they would be stupid to not do it and why is every airline not doing it?

But LED’s are not without their problems. They are not the everlasting lamp that we have been led to believe by manufacturers. In fact depending on the fitting and how hot it gets, a lamp can severely discolour and grow dim within months. This is where Dyson’s design is somewhat unique.

“LEDs are semi conductors,” Dyson reasons aloud, “and semiconductors are used in computers. And the way they cooled semiconductors in computers was using heat pipes.” The solution it seems is in the cooling of the lamps. The way to do that? Heat pipes. Heat pipes are copper tubes with a vacuum inside. Inside that vacuum is a single drop of moisture. The water evaporates at very low temperatures in a vacuum, so the internal build up of heat transforms this water into vapour, the vapour shoots from the hot end of the heat pipe to the cool end. The water then cools and condenses, making its way back to the hot end of the pipe. The cycle repeats to create an infinite loop of efficient, passive cooling.

[xyz-ihs snippet=”jake-dyson”]

Introducing this idea into his latest lamps Jake Dyson thinks he has achieved the ability to make his lights last 30 years or more with no loss of colour or efficiency. So what are the plans for this technology and will we see it filter through to the commercial and industrial sector? Well perhaps, yes, soon with the suspended Ariel™ LED light, Jake Dyson has developed core lighting technology to overcome the problems presented by current LEDs.

Jake Dyson said, “We’ve been developing technology to harness the power of LEDs for over ten years, creating lights for the home which are long-lasting and produce a high quality of light. Our cooling technology sits at the core, and means we’re able to use a high density, high powered LED light source which our competitors can’t. We’ve already got an ambitious pipeline of technology and I will help drive the broader application of technology at Dyson.”

The CSYS™ task light uses heat pipe technology, which dissipates heat generated by the LEDs through an aluminium heat sink. Eight high power LEDs project warm, white light, which can be positioned exactly where you want it using 3 Axis Glide™ motion. Touch-sensitive continuous dimming means you  can choose exactly the level of light you need. But I think the real breakthrough shall be the Ariel™ light, compact and efficient, a ceiling mounted downlight which uses the latest LED technology to evenly illuminate a specific working area such as office desks, a boardroom table or kitchen island. Heat pipe technology ensures that heat is dissipated away from the LED to maintain performance. Following three years of research and development, it is expected to be available later this year. I am sure if this prooves a success it wont be long before more follow.

can choose exactly the level of light you need. But I think the real breakthrough shall be the Ariel™ light, compact and efficient, a ceiling mounted downlight which uses the latest LED technology to evenly illuminate a specific working area such as office desks, a boardroom table or kitchen island. Heat pipe technology ensures that heat is dissipated away from the LED to maintain performance. Following three years of research and development, it is expected to be available later this year. I am sure if this prooves a success it wont be long before more follow.

Budget Airlines – Small Plane More Space0

New spacious design brings hope to budget travellers

New spacious design brings hope to budget travellers

Summer holidays are upon us and with the majority of holiday makers now using budget airlines, squeezed into a tiny space with no thrills, it often leaves us wondering is this the best we can do? Well apparently not, airlines can do better!

Design company Preistmangoode have come up with an ingenious design for a commercial plane that will make it’s economy passengers feel they have been upgraded.

With enough room for every single passenger to fit an airline standard piece of carry on luggage wheels in first in the overhead bins and because there are no legs between the seats, passengers can also fit large items under the seat in front of them, providing unrivaled carry-on capacity.

With enough room for every single passenger to fit an airline standard piece of carry on luggage wheels in first in the overhead bins and because there are no legs between the seats, passengers can also fit large items under the seat in front of them, providing unrivaled carry-on capacity.

Prietsmangoode looked at increasing personal territory and enabling passengers to reclaim their own space. One of the key ways in which we were able to do this was by installing the first of its kind passenger focused PSU (patent pending). This enables passengers to control the light and air condition of their seat without disturbing the passenger next to them.

Prietsmangoode looked at increasing personal territory and enabling passengers to reclaim their own space. One of the key ways in which we were able to do this was by installing the first of its kind passenger focused PSU (patent pending). This enables passengers to control the light and air condition of their seat without disturbing the passenger next to them.

The internal windows have been designed to appear larger, creating a greater feeling of space. The designs offer a clean, contemporary cabin that not only enhances passenger experience, but significantly improves efficiency and maintenance for airlines and leasing companies alike.

The internal windows have been designed to appear larger, creating a greater feeling of space. The designs offer a clean, contemporary cabin that not only enhances passenger experience, but significantly improves efficiency and maintenance for airlines and leasing companies alike.

The team at Preistmangoode worked closely with Embraer, a Brazilian manufacturer who are currently the third largest producer of aircraft after Airbus and Boeing. Priestmangoode’s goal was to design a cabin with a clear differentiation from competitors in narrow body aircraft manufacture.

Currently two UK based airlines use these low capacity single aisle cabins, Flybe and BA CityFlyer, but with the new design unveiled at the Farnborough airshow in July, it may not be long before we see more budget airlines taking on the planes.

[xyz-ihs snippet=”new-plane-design”]

This is the latest project in a long-standing relationship between the London and China based design studio and the Brazilian company, following Priestmangoode’s design for the Embraer Lineage 1000 executive jet interior.

Paul Priestman comments:

“We have a long standing relationship with Embraer, and this project has cemented a fruitful partnership between our companies. Embraer is continuously investing in its fleet, research and development and shows great design leadership, and commitment to the passenger experience and long term sustainability”

The new Embraer jet is scheduled to take off in 2018.

Pictures by Priestmangoode

Dyson Wants His Famous Vacuum to Clean Rivers0

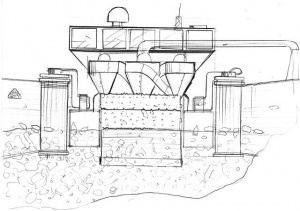

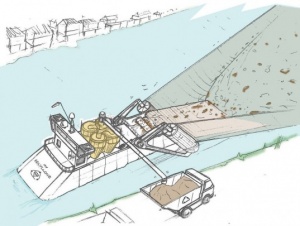

In a recent interview with TIME magazine, James Dyson expressed his concerns over the cleanliness of the worlds rivers and the affect it has on local wildlife. The solution? An upscale Dyson vacuum to remove all the rubbish.

The concept is based around a barge that have nets to collect the plastic debris and a cyclone suction system similar to that used in his vacuums pulls in the waste where it is then separated. Dyson admits he is still working out how to keep the aquatic wildlife safe.

“Large skim nets unfurl from the rollers at its stern and are anchored on each side of the river. Hydraulic winches wind them in and out. The nets face upstream and skim the surface of the river for floating debris. The plastic waste is shredded on board and then different grades of plastic are separated by a huge cyclone–very similar to the way our cyclonic vacuums work,” he said.

“The concept I propose, the M.V. Recyclone, would combat this ever growing problem of plastic waste making its way to our oceans by filtering out debris from the rubbish-stricken rivers that feed into them. By focusing on the polluted rivers, the M.V. Recyclone could tackle a concentrated stream of plastic, catching it before it spreads.”

James Dyson has sketched out his idea for both TIME magazine and for Fast Company and we will be keeping a close eye on the progress although even Dyson himself admits that there is still a lot of work and fine tuning before we even see a prototype.

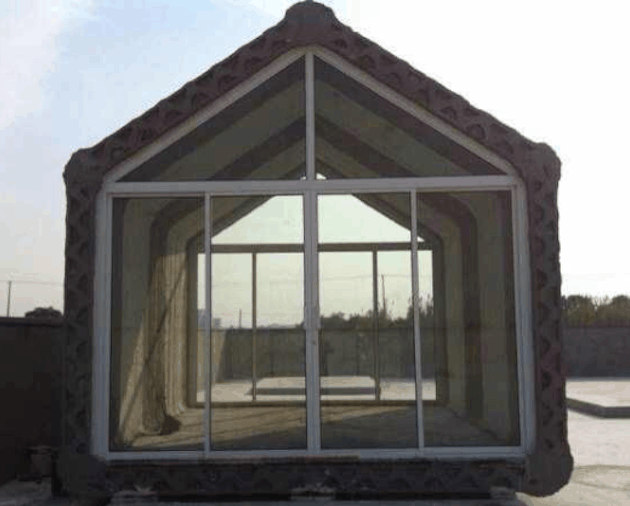

3D Printed Affordable Houses1

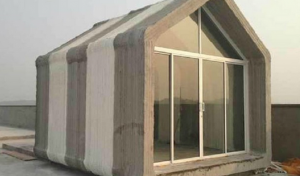

Chinese Company Assembles 10 3D-Printed Affordable Houses in a Day

OK so they are not pretty and wouldn’t feature on Grand Designs but never the less this is a remarkable achievement and a huge step forward in the development of 3D printed architecture. The possibilities this could bring are endless and considering the cost of each unit was a meager $4,800.00 it certainly comes to mind these could be used to provide emergency housing by areas affected by natural disasters and wars. This is a far cry from the stylish 3D printed Canal Houses in Amsterdam by DUS architects but it

does lead they way into 3D printed affordable housing.

The Shanghai building company, WinSun Decoration Design

Engineering Co. recently constructed a small community of partially 3D-printed houses in less than a day. The Chinese company printed the basic components separately before assembling them on site.

A 3D printer measuring 150 meters long, 10 meters wide, and 6 meters deep was used to 3D print each of the structural components from the giant concrete slabs to the inner cross bracing. As a cost cutter, WinSun fabricated the frame from layers of concrete partly made from recycled construction waste, industrial waste, and glass fibers.

The company also plans to open 100 recycling factories in the country to continue to transform waste into cost-effective “ink” for their 3D printers. Winsun estimates that this kind of 3D printing could cut costs for construction companies in half.

BMW Designs Plush Subway Trains for Kuala Lumpur’s Metro0

Designworks USA, a BMW subsidiary, is helping the the Malaysian government’s plan to encourage the city’s growing population to use public transport by designing plush new trains for the brand new three-line metro system in the city of Kuala Lumpur.

Siemens asked DesignworksUSA to help on the innovative Metro Inspiro, to develop the design for the new underground passenger trains. A total of 58 trains will be in service as of 2017 on one of the most frequented lines of the city. The new Metro system will incorporate energy-efficient LED lighting, recyclable stainless steel cars, and an aesthetically pleasing mix of futuristic feature. When operational the driverless trains will be in service allowing a frequency of one train every 3.5 minutes during peak hours. Each four-car trainset will have a capacity of 1.200 passengers improving the daily ridership target of the operator. The train design also takes into consideration the needs of disabled people: Six specific areas in each train are equipped with hand-rails which offer sufficient space to allow wheelchair-bound passengers to be seated in their rides. The doors will emit a beeping sound and light to guide disabled passengers when the train doors are closing and opening.

Identity was a key driver in the design development of the new Metro Inspiro for Kuala Lumpur: The cityscape is characterized by a mixture of cultures and religions manifested in a rich architectural diversity. Tradition and progress are at the heart of the people’s pride and self confidence and also inspired the design concept for the new metro. Under the name “Guiding Light” the design of the Metro Inspiro takes a bow to the rich heritage of Kuala Lumpur and makes a strong statement towards the future. A metropolis’ identity is notably determined by the quality and visual impression of its local public transport system.

Identity was a key driver in the design development of the new Metro Inspiro for Kuala Lumpur: The cityscape is characterized by a mixture of cultures and religions manifested in a rich architectural diversity. Tradition and progress are at the heart of the people’s pride and self confidence and also inspired the design concept for the new metro. Under the name “Guiding Light” the design of the Metro Inspiro takes a bow to the rich heritage of Kuala Lumpur and makes a strong statement towards the future. A metropolis’ identity is notably determined by the quality and visual impression of its local public transport system.

“The exterior design is a bold statement of dynamism and strength. It symbolizes self confidence, technological leadership, progress and safety,” says Laurenz Schaffer, President of BMW Group DesignworksUSA. The light concept in the front of the train bears a strong graphical character. It is a reference to the facetted architecture of the capital.  In the train interior the interplay of past and future continues: The lively colour concept with varying shades of blue and traditional symmetrical patterns is a fresh interpretation of the vitality and cultural diversity of Kuala Lumpur. Color contrasts in the door areas help guide passengers and enable an easy entrance or exit. The train interior features an LED lighting system. The use of indirect light beneath the seats creates a feeling of spaciousness and safety and enables easy maintenance of the trains.

In the train interior the interplay of past and future continues: The lively colour concept with varying shades of blue and traditional symmetrical patterns is a fresh interpretation of the vitality and cultural diversity of Kuala Lumpur. Color contrasts in the door areas help guide passengers and enable an easy entrance or exit. The train interior features an LED lighting system. The use of indirect light beneath the seats creates a feeling of spaciousness and safety and enables easy maintenance of the trains.

The new metro for Kuala Lumpur also has a convincing environmental record:

The trains which have a 30-year life-cycle are approximately 95 percent recyclable. They consist of light weight stainless steel car bodies, weight-optimized components and employ highly efficient air conditioning and lighting systems which substantially reduce energy costs.

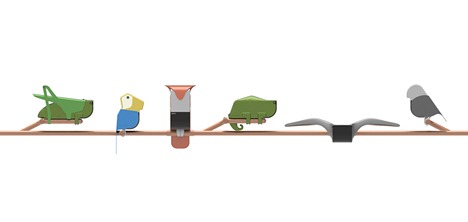

Aluminium animals disguise CCTV cameras

Italian designer Eleanor Trevisanutto has been commissioned by an Italian company Parsons to transform security equipment in to animal characters.

These aluminium CCTV camera cases are designed to make electronic surveillance seem less intimidating perfect perhaps for a Zoo or childrens nursery.

This colourful idea was initially designed to create an aesthetically pleasing alternative to the otherwise harsh world of surveillance equipment. While some may argue that security cameras are intimidating for a reason, it ultimately succeeds in brightening up and lightening up the enviroments that rely on a calm atmosphere. Each camera is encased within brightly coloured, sand-cast aluminium, which resemble a series of tree-dwelling animals.

The camera lens is hidden behind a semi-transparent black screen and the cameras attach to a wall via an armdesigned to look like a tree branch, with electrical cables concealed inside.

and the cameras attach to a wall via an armdesigned to look like a tree branch, with electrical cables concealed inside.

There are seven different animals but these are not currently for sale, anyone interested however can sign up to the Parson website.

[images by Parson]

Wireless Charging for Cars is the future0

An all-electric bus route featuring wireless charging technology has been launched in Milton Keynes. Wireless charging plates installed in the road transfer energy to receiving plates under the bus, recharging its batteries enough to help it complete the town’s 17-hour daily bus service.

The buses will run for five years in a carefully monitored demonstration programme, which will objectively assess their technical and commercial viability.

Eight electric buses will take over a route that even diesel buses find demanding: running 17 hours a day, seven days a week, with each bus covering over 56,000 miles per year. However, the Milton Keynes buses have wireless charging to help them meet the demands of their route.

Instead of plugging into the mains, the new buses will be able to recharge their batteries wirelessly during their working day. This means they can run a continuous service for a whole 17 hours, just like a diesel bus. The concept is simple: wireless charging plates set into the road transfer power directly to receiving plates underneath the bus, using a technique based on the principles of electrical induction. In just 10 minutes, a bus parked over a charging point will replenish two-thirds of the energy consumed on its 15-mile route. Only two wireless charging points are needed to service all eight buses, which will charge in the time scheduled for driver breaks.

With this new technology we ask how long will it be before this can be adapted and implemented into the house hold car? Already two car manufacturers have enabled their cars to accept wireless charging: Nissan LEAF and Chevrolet Volt how long will it be before the others follow in their footsteps.

In September 2013 the FIA international motorsports body announced plans to launch the electric-car competition in 2014 as an alternative to Formula 1. Qualcomm signed up as a sponser and announced its commitment to provide wireless-charging and augmented-reality technology to help the teams taking part and the public watching the races.

The wireless vehicle-charging tech, Halo, is being developed by the company’s London-based lab – creates an electromagnetic field using a copper pad buried in the ground. This can be picked up by a coil built into a vehicle, which converts it into electricity to power-up a battery.

British Formula E team Drayson Racing Technologies has already tested a customised version of Halo as a way of charging its vehicles when they are stationary.

In time, Qualcomm said, several pads could be built into the city centre roads used by the races to provide “dynamic charging” – the ability for the cars to top up their power on the go, helping them complete the race in quicker time. So isn’t it about time that we looked into whether this is feasible to roll out on our public roads? How long before wireless charging for cars is rolled out and thus making the electric car a more attractive option for everybody?

First 3D printed House to be in Amsterdam!0

The first 3d printed house will be built in Amsterdam. This Year!

3D printing is already advancing quicker than most anticipated and is being used every day for the electronics sector for constructing custom enclosures and soon added to that will be air ducts, conduits and motor mounts.

The new sector is now being used for military devices and for one of medical devices like prostheses.

Mick Ebeling, is the founder of an American startup called Not Impossible Labs. In November 2013, Ebeling travelled to Sudan for a month after hearing of a 14 year old bomb victim who had lost both hands. Thus was created Project Daniel. He took with him printers, spools of plastic and cables. The 3D printers that create the prosthetic’s plastic parts make the device seem hi-tech, but the resulting arm is really just a simple, mechanical device. Since Ebeling has returned home, one prosthetic a week has been printed, thanks to two 3D printers he left behind. The printed parts are then collected by eight local people trained to operate the machines, assemble the arms, and customise them for recipients.

So how does this technology fit in with the construction industry?

Back in 2012, two technologies, Contour Crafting and 3D concrete printing, promised to build homes in less than 24 hours using a 3D printer. Both Contour Crafting and 3D concrete printing have made progress, but not enough to print a house in a day. But now it looks like that is all about to change, this year we will see the first 3D printed house, but with someone new!

DUS Architects from the Netherlands is going to take a crack at it with a publicly funded project called 3D Print Canal House.

The company will be taking advantage of the 400-year-old tradition of building canal houses to prove that 3D printed housing is not only possible, but financially feasible.

The 3D printer being used in the construction is one of the largest yet. The printer itself has a build volume of 2x2x3.5 meters. The 3D printer will be able to print 6x6x11 foot rooms that will then be assembled into a house.

DUS Architects won’t say what kind of material they’re using yet, but it’s reportedly a sustainable material built by adhesives company Henkel.

To help support the project, Amsterdam will allow the public to observe the 3D printer as it makes the house as part of what it calls the Construction Expo starting March 1. There will be an admission fee which the city will use to fund the project in the long term.

[xyz-ihs snippet=”80355705″]